General principles

Dry coolers and condensers are normally selected to operate correctly at maximum thermal load with maximum ambient temperature.

However, these severe working conditions apply only to a brief period of the year whilst for the remainder of the year – in less severe conditions – the machine is oversized. This is why LU-VE designed a unit which can be selected for standard working conditions but which can increase its performance when particularly severe conditions arise.

With this system the air crossing the coils can be cooled, obtaining an increase in capacity of the dry coolers and condensers.

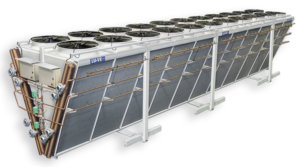

Adiabatic Dry coolers and condensers with special spray systems WSS

Function

This new product is realised by applying a special spray system to dry coolers and traditional condensers. Water is finely atomized and sprayed in the opposite direction to the air flow goiung through the coils.

This new product is realised by applying a special spray system to dry coolers and traditional condensers. Water is finely atomized and sprayed in the opposite direction to the air flow goiung through the coils.

The Water Spray System is made up of:

- two electromagnetic valves

- a manual outlet valve

- a water pressure gauge

- a pressure switch for the water

- two racks of special nozzles to nebulize the water

The two electromagnetic valves permit two levels of regulation of the system. If the pressure is insufficient, the pressure switch interrupts the water flow and signals an alarm.

Applications

Large capacity dry coolers

Large capacity condensers