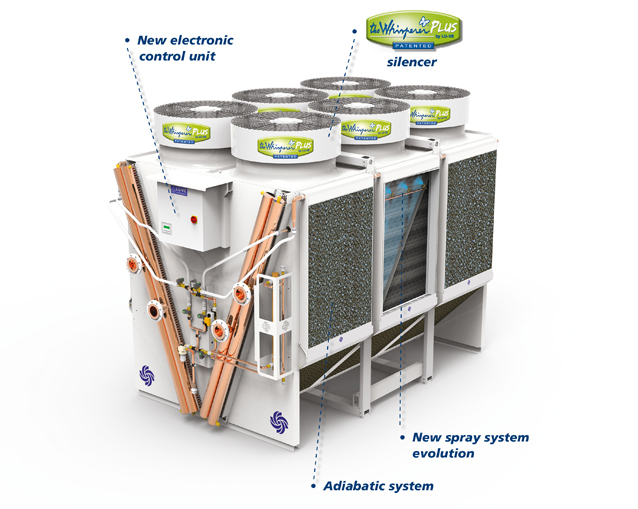

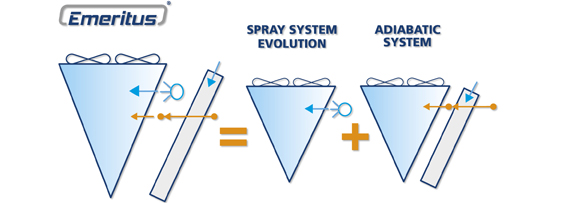

The new combined spray + adiabatic system

400% MORE CAPACITY THAN A DRY EXCHANGER

EMERITUS® is the latest innovation developed for the dry cooler, condenser and CO2 gas cooler families from LU-VE Exchangers.

Available for: HFC, NH3, Propane, CO2

The operating principle of Emeritus®

This new technological advance (patent pending) is the result of collaboration with the Polytechnic University of Milan and brings together the benefits of spray systems and adiabatic pre-cooling, all assisted by an advanced control system.

Applications

The specific features of this product make it especially suitable for use in air conditioning and refrigeration. When EMERITUS® is applied to CO2 gas coolers, high system COP can be reached even during the hottest hours of the year, extending the geographical limits where trans-critical systems can be cost-effectively constructed (the “CO2 equator”).

The Advantages Of Emeritus Technology®

Power

up to + 400% compared to traditional dry ventilated exchangers

Efficiency

Reduction of the operating DT1 with benefits on the plant COP

Noise

reduction up to 6 dB (A) of the sound level for the same power

Savings on electricity consumption

up to 60%

Reduced refrigerant charge

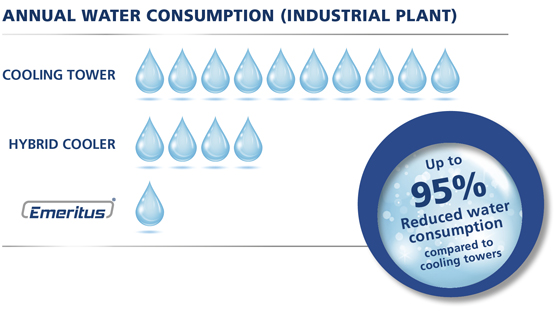

Reduction in water consumption

up to 95% (compared to traditional operating towers)

Automatic water quality control

equipped with sensors that continuously monitor water quality

Protection

The finned pack is made of a new magnesium-aluminum alloy coated with a special treatment (ALUPLUS ® ) that guarantees a high protection against corrosion

Reduced Water Consumption

Using liquid coolers and EMERITUS® condensers as an alternative to traditional condensers and evaporative towers leads to significant advantages in terms of water consumption.

Intelligent Control System

With innovative and easy to use functions, in addition to the management of electronic ventilation (EC), the sophisticated software stores the amount of hours of operation of each ramp of the spray circuit and of each adiabatic panel. Thanks to the “rotation logic” it determines which system to activate, optimizing the number of operating hours in spray mode.