What Does Adiabatic Mean?

The term “adiabatic” means “occurring without gain or loss of heat,” but applying this definition to common industry terms requires distinguishing between heat and temperature. When a gas is compressed under adiabatic conditions, its pressure increases and its temperature rises without the gain or loss of any heat.

Conversely, when a gas expands under adiabatic conditions, its pressure and temperature both decrease without the gain or loss of heat. A good example is the adiabatic cooling of air as it rises in the atmosphere to form clouds.

How Do Adiabatic Cooling Systems Work?

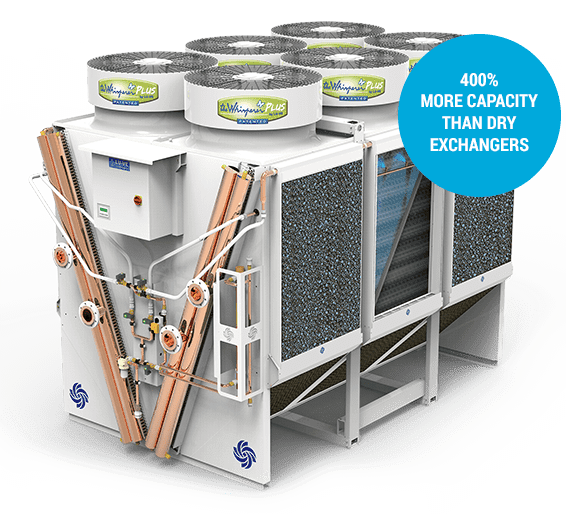

Adiabatic coolers work by using evaporation to pre-cool the air flowing through a closed loop coil.

Imagine a fluid cooler running fans but with the spray pump off. If the air is cool enough, the loop temperature is low enough to keep the system going whether it is HVAC or process cooling. Now, picture a series of cooling misters in the air intakes of the fluid cooler. When fine mist of water entering the fluid cooler rapidly evaporate, absorb from the air the latent heat required for evaporation and, therefore, cause the temperature of the air to decrease.

Now the air entering the fluid cooler is low enough to deliver the right temperature water back to the process. Adiabatic cooling systems work on the same principle, but use a variety of means to pre-cool the air before it flows through the coil. Wetting pads, thin film fill, plastic mesh and mist nozzles are commonly used to create enough surface air for the water to quickly and completely evaporate.

So How Do Adiabatic Fluid Coolers Save Water?

Adiabatic cooling systems save water by operating as a dry cooler whenever the load is light enough or the air is cool enough to do so, drawing ambient air across the closed loop heat exchangers to remove the heat from the process. When ambient temperatures begin to rise or load conditions increase, fan speed also increases, if temperature can not be maintained, a wet mode is achieved by spraying mains water over the pre cooler pads to pre cool the air entering heat exchanger, eliminating the need for evaporation of the process water like in a traditional open cooling tower system.

Do Adiabatic Cooling System Costs Less to Operate?

Saving water is important, but it must be balanced with the total cost of operation. Adiabatic systems cost less to operate when compared to traditional cooling tower systems. There is no need to register an adiabatic cooler for compliance, there is no monthly ongoing chemical treatment costs, there is a significant reduction in energy consumption and 95% less water consumption per annum when compared to traditional cooling tower systems.

Do Adiabatic Cooling Towers Have Scale Problems?

While manufacturers downplay the scale problems in their wetted pads and thin film fill, we know from experience that anytime water evaporates to dry, salts of evaporation form.

Traditional cooling towers are engineered to minimize the impact of dry off, but adiabatic systems are designed specifically to evaporate water completely to dry. Calcium carbonate scale will accumulate on the wetted surfaces of the adiabatic system just like it does where water evaporates completely to dry on any cooling tower.

Do Adiabatic Fluid Coolers Have Legionella Concerns?

Legionella can be a problem any time warm water is used to create aerosols.

Much like traditional cooling towers, some adiabatic designs are prone to Legionella issues. Risk often comes down to design and engineering. The main benefit from Adiabatic Fluid coolers vs cooling towers is the closed loop design where process water does not come in contact with the ambient air eliminating the risk of Legionella. Accessories to the system such as buffer tanks and water spray collection tanks should always be properly maintained to eliminate the risk of Legionella.

What Water Treatment Equipment Should I Recommend for an Adiabatic Cooling System?

Water supplying the wetted pad or mist nozzles is generally not recirculated and is designed to evaporate completely so no water treatment is needed.

While these features are not sumps to collect recirculating water, system design varies and the water that collects at these points may benefit from treatment to prevent corrosion and microbiological growth. Marketing brochures always show clean systems, but experience proves that they do not stay clean without proper treatment and preventative maintenance.

ADIABATIC COOLER VS COOLING TOWER

Adiabatic Cooler vs Cooling Tower – Considering replacing or acquiring new equipment? Read on to weigh up the pros and cons…

Adiabatic Cooler

- Spray cooling kicks in only when the ambient air temperature is too high to use cooled air

- Only uses mains cold water when high ambient temperatures demand higher levels of cooling. To put this into context, the capital cost of an Adiabatic Cooler and its first 25 years of water consumption is considerably less than the first year of water consumption of a Cooling Tower

- These units produce smaller droplets of water; between 50 and 100 microns which cannot support bacteria growth. The system also features a UV disinfection system as a failsafe to kill any traces that may make its way into the system, further minimising the risk to health

- These units do not need to be registered with the Health and Safety Executive as the risk of legionella is all but removed

- Adiabatic coolers have an auto drain down function to empty the system of water

Cooling Tower

- Water is continually sprayed to cool the condenser coils, continually using a mains water supply to create a cooling effect

- Water isn’t drained from the cooling tower which can facilitate the growth and spread of legionella bacteria; the water droplet size produced and the process temperatures are ideal to breed the bacteria, consequently regular servicing, chemical treatment and strict HSE guidelines need to be followed

- Due to the evaporation rates of Cooling Towers (1.6kg water evaporated for every kW of heat removed) the water and chemical costs to maintain the fluid chemical balance can quickly mount up to tens of thousands of dollars

- These systems need to be registered due to the high risk of legionella

In summary, there are several benefits of using an Adiabatic Cooler:

- Save thousands of dollars in running costs

- Industrial water saving

- Does not require further chemical treatment

- Energy efficient cooling

- Controlling legionella prevention

For more information about our range of adiabatic cooling solutions or to arrange a free site survey, contact us on 03 9357 5768

ADIABATIC COOLERS – COST-EFFECTIVE COOLING

Adiabatic Coolers are a cost-effective and environmentally friendly alternative to Cooling Towers – requiring significantly less maintenance, reduced legionella risk and operational costs. They require no ongoing chemical treatment or registration with local authorities and use less than 0.5% of traditional Cooling Tower water usage.

The units use fans to operate the cooling for a high percentage of the year with a spray system which only activates during periods of high ambient temperatures. The spray activity is tightly monitored using a pulsing mechanism to ensure minimum adiabatic cooling is provided for any given load and ambient condition. This control reduces water consumption and running costs for a long, fault free lifespan.

- Spray cooling kicks in only when the ambient air temperature is too high to use cooled air – save thousands of dollars in running costs

- Only uses mains cold water when high ambients demand higher levels of cooling – conserving water

- No need to register with the Health and Safety Executive as the risk of legionella is all but removed

- No further chemical treatment required – saving you resource and budget

Our Adiabatic Coolers are designed to meet your requirements including footprint, acoustics and construction materials. Overall, they offer significant energy and operational savings – helping you to boost productivity and efficiency of your site.

Features include:

Variable speed EC and AC fan technology

- Easy-to-use PLC control panel

- WI-FI and 3G connectivity for BMS integration

- Multiple fixed fan speeds

- Inverter speed control

- Free Cooling available

- Coatings for extreme external environments